How Are Glasses Made?

Reviewed by

Beck Jinnette

If you wear glasses, you know what a big difference they make to your quality of life. Your first thought every morning may well be, “Where are my glasses?” such is their importance.

They’re readily available, they improve the lives of everyone who uses them, and if you break or lose them, you know how to go about getting another pair.

Despite being aware of all this, and grateful for their existence, it’s unlikely that you know all of the ins and outs of how they are produced.

In this article, we’ll delve into the intricate process of manufacturing glasses, from frame fabrication to lens crafting, explaining how those specs sitting on the bridge of your nose ended up there.

Creating the frames

Just as there is a wide variety of eyeglass frame shapes available, there are a number of different frame materials, from metal and plastic to eco-friendly options. Here, we’ll take a look at the processes involved in making acetate frames.

Acetate is a plant-based plastic known for its flexibility and hypoallergenic properties, making it a prime material for eyeglass frames. The journey of turning acetate into fashionable frames involves a few crucial steps.

Cutting, counter-boring and riveting

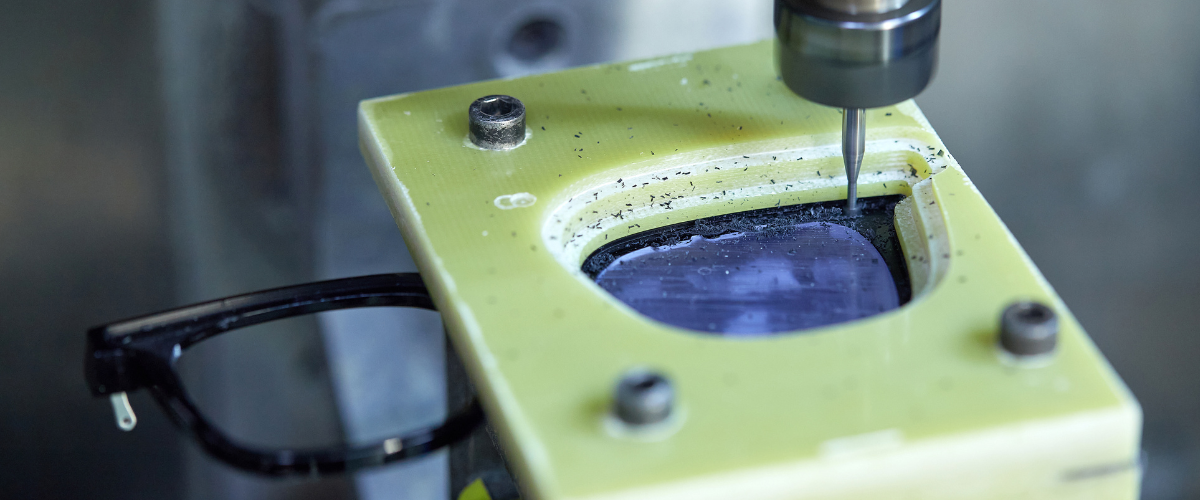

The initial cutting stage in crafting acetate glasses frames requires a lot of precision and expertise. Beginning with large sheets of acetate, high-tech cutting machinery carves out the desired frame shape.

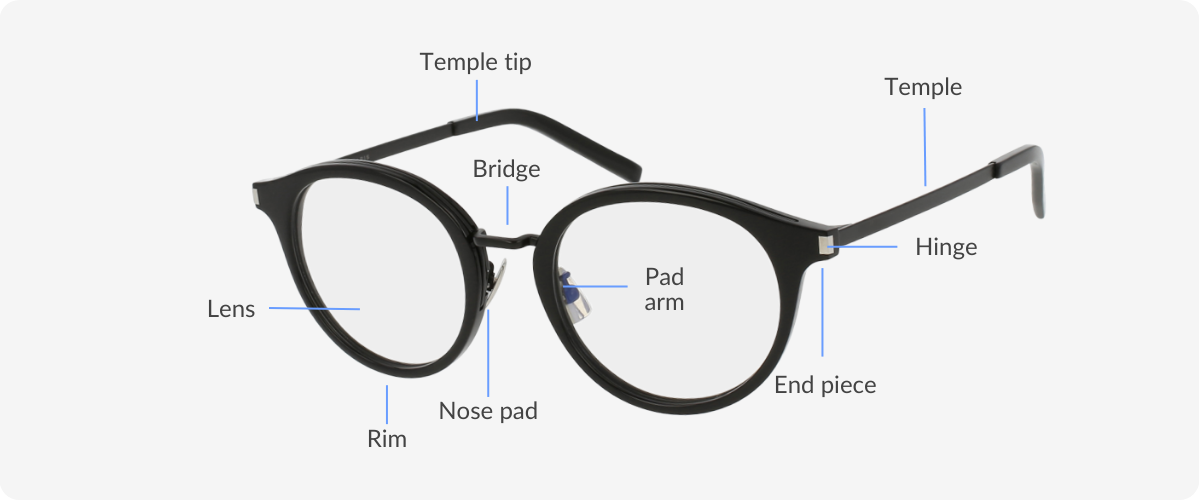

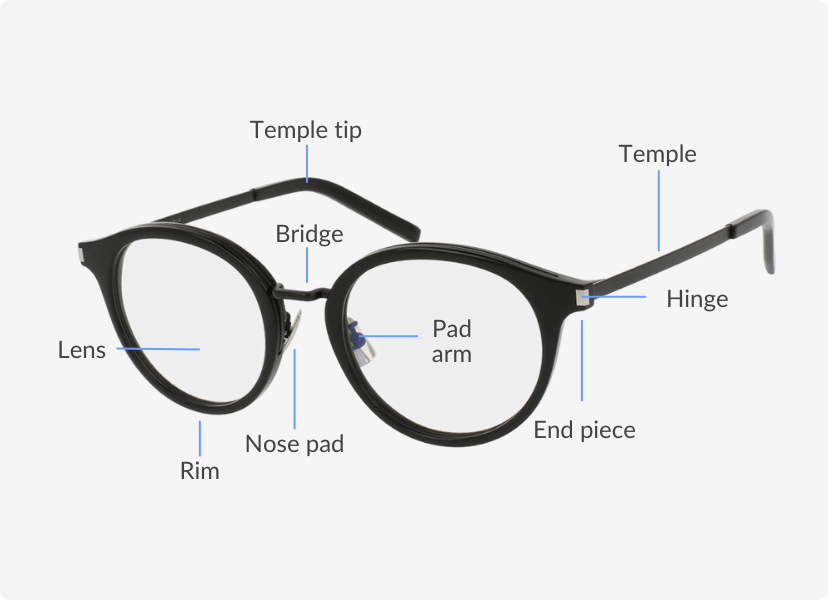

Once the basic form has been constructed, “counter-boring” comes into play, creating recesses in the frame where the hinges will be placed. This ensures a seamless and secure connection between the frame and its other components.

Finally, “riveting” solidifies this connection. Small rivets, typically made of metal, are meticulously placed and secured, ensuring hinges and other integral components stay in place and function as intended, promising both durability and ease of use.

Curving, polishing and blasting

Once the basic shape of the frame is realised, the focus shifts to refining its esthetics and ergonomics. “Curving” is the process by which the frames are given their distinct contour, allowing them to rest comfortably on the wearer’s face.

The frame is heated slightly to make it malleable, then molded into the desired curvature and plunged into cold water to help it keep its new shape.

After curving, the polishing process ensures the frame gleams and is free of any rough edges. Frames are often tumbled in barrels with small stones and polishing agents or buffed manually to achieve a smooth, shiny finish.

As a final touch, fine particles are “blasted” at the frame’s surface. This process can be used to create unique matte finishes or to further smooth the frame, ensuring the end product is both stylish and comfortable.

Temple machining and pad printing

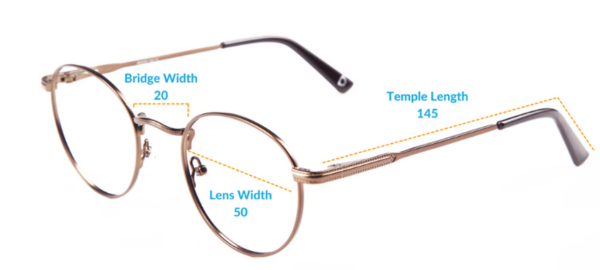

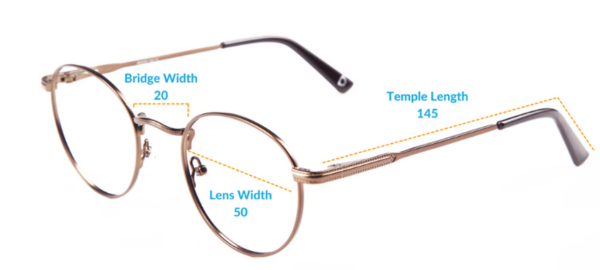

The temples (or arms) of the glasses are as crucial as the frame itself. “Temple machining” refers to the crafting and refining of these essential components.

Precision machinery ensures the temples are perfectly symmetrical, with the right length and curve to comfortably hook behind the ears.

Additionally, certain features like spring hinges may be incorporated to provide flexibility and enhance the wearer’s comfort. Once machined to perfection, many brands choose to leave their mark on these temples, a process known as pad printing.

Using a silicone pad, the brand’s logo or specific design is delicately stamped onto the temples. This not only signifies authenticity but also adds a touch of elegance and brand pride to the finished product. The frame is then fully assembled by screwing the temples onto the frame front.

DID YOU KNOW?

The first glasses frames were made from materials found in nature, like animal bones and tortoise shells.

Manufacturing the lenses

As important as the frames are from both a functional and stylistic perspective, the eyeglass lenses are, of course, the most essential part of prescription glasses. Plastic lenses have become more commonplace than glass lenses over the years, thanks to their greater durability.

The production process, however, is the same for both kinds. Today, it is almost entirely automated, using cutting-edge technology and machinery.

Preparation

In order to produce eyeglass lenses, a comprehensive understanding of the wearer’s visual needs is essential. After an eye examination, optometrists translate the results into a prescription.

This prescription dictates the lens power, curvature and type, serving as a blueprint for the upcoming manufacturing process.

The appropriate material, be it polycarbonate, high-index plastic, or CR-39, is chosen based on prescription requirements and individual preferences, as indicated in the customer’s order.

Blocking

Before the plastic lens is shaped, it’s vital to secure it in place for precise carving. A protective block, often accompanied by a layer of protective adhesive or alloy, is attached to the lens blank.

This block serves multiple purposes: it acts as a grip for machinery, ensures that the lens remains steady during subsequent processes, and protects it from potential damage.

Generating

With the lens securely blocked, it’s time to carve its perfect shape. The generating phase involves grinding the lens blank using computerised lens-grinding machines.

These machines precisely cut the plastic eyeglass lenses according to the prescription’s specifications, ensuring the correct power and curvature.

Polishing and engraving

After generation, the lens surface may be slightly rough and cloudy. To achieve a flawlessly clear and smooth finish, the lens undergoes a polishing procedure. Using soft pads and polishing compounds, the lens is buffed until it gleams.

Some lenses, especially those with multifocal capabilities, might be engraved with tiny markings, indicating different viewing zones. This engraving aids opticians in aligning the lenses correctly.

De-blocking and cleaning

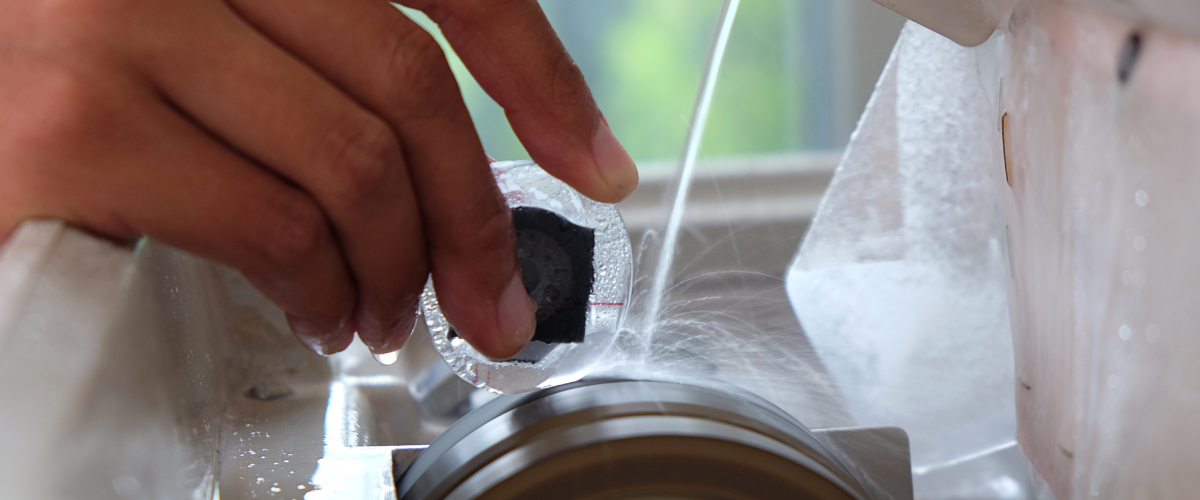

Once polished and potentially engraved, the lens no longer needs the block used during the generating process. The de-blocking step involves carefully removing the block, and the lens is subsequently cleaned.

Any adhesive residue or contaminants that might have settled during the manufacturing process are thoroughly removed, ensuring optical purity.

Tinting and coating

To enhance the lens’s functionality and aesthetic appeal, it might undergo tinting or receive various coatings. “Tinting” involves immersing the lens in special dyes, allowing wearers to achieve a particular shade or gradient.

Coating processes can range from applying anti-reflective layers, which reduce glare, to UV coatings that block harmful rays, and even scratch-resistant coatings that protect the lens from everyday wear and tear.

Quality assurance

The final, yet crucial, step in the lens-making journey is “quality assurance”. Every optical lens is meticulously inspected to ensure that the prescription parameters are spot on.

Advanced equipment checks the lens’s power, curvature and thickness. Any blemishes, inconsistencies, or imperfections are identified, and only lenses that meet strict quality standards make their way to the wearer.

Lens fitting

Now that the two main components are ready, it’s time to combine them for the finished product. Once again, the frame is gently heated, and the eyeglass lenses can then be inserted more easily into the groove.

This step is commonly performed by an optician, who will have received the prescription lenses and can fit them into the customer’s frame of choice.

So now you know how glasses are made. If your curiosity still isn’t satisfied, look at some of our other informative articles in our Optical Center, or ask our opticians if you don’t find the answers you’re looking for there.

Related articles

Related articles